The Traditional Methods:

DRY PROCESS: The simplest, most straightforward, conceptually, but can also be the hardest for some to execute. Often, the term dry process can be used interchangeably with "natural" process.

After harvesting the ripe fruit, the fruit is laid out to dry on concrete patios, like they do in Brazil, or on rooftops, like in Yemen, or they could be laid out on raised beds like they do in Ethiopia. Alternatively, they can also be mechanically dried in big rotating ovens. We often don't opt for the mechanically dried as it can lower cup score, yet it can be more efficient, specially if there is a shortage of patio space.

WET PROCESS: This is also known as "washed" process, and uses lots of water. We have typically avoided the term washed because it could imply other processes can be "dirty" when that simply isn't the case, and it's more about "washing" all the fruit stuff away.

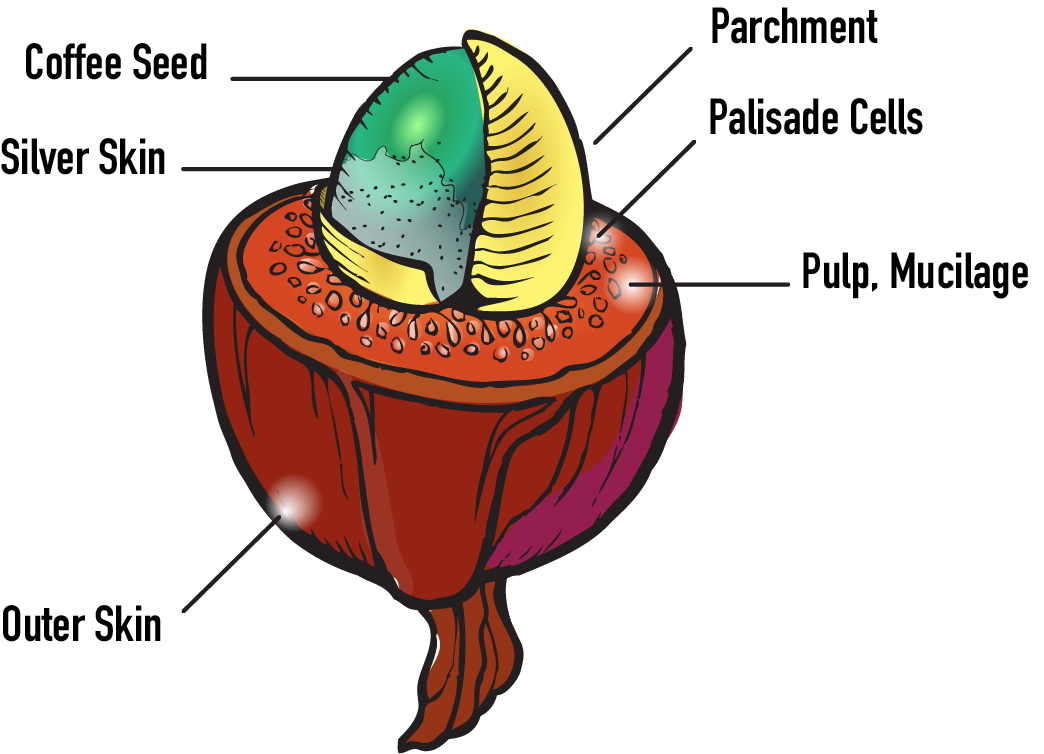

After harvesting the ripe fruit, the fruit is rinsed off of any debris and soil from the trees and the field. it is then moved to a piece of machinery called a de-pulper (or confusingly enough; a pulper) to have the skin removed. That skin can then be dried into cascara. As for the slimy coffee fruit this is where it can go to be either honey or continue onto being washed. after de-pulping, the slimy beans are still covered in a very fibrous mucilage that is very challenging to mechanically remove (but not impossible), so typically leaving them to "ferment" in a large tank (typically a concrete silo, preferably tiled for cleanliness) for 12-72. The duration depends on environmental factors and temperatures. typically the coffee is not submerged under water, and can develop lots of heat from multiple chemical and enzymatic reactions. The idea is to only breakdown the mucilage enough so that parchment bean can later be moved through canals with water to knock off whatever remainder mucilage there is to then move the washed parchment to drying patios, raised beds, or even mechanical dryers (none of the coffees we purchase are mechanically dried, we strongly feel that heat at this stage of the process lowers cup quality).

HONEY PROCESS: also sometimes called pulped natural (in Brazil, because there isn't the ferment or washing aspect). It is also sometimes referred to as "semi-washed", but in an attempt to avoid ambiguity, we avoid the term as it can also be synonymous to "wet hulled" which is totally different, and provides a very different cup profile.

Honey processing in it's simplest understanding starts off just like wet processed lots; after harvest, the fruit is rinsed off of any debris and soil from the trees and the field. it is then moved to a piece of machinery called a de-pulper (or confusingly enough; a pulper) to have the skin removed. That skin can then be dried into cascara. This is where the differences between wet and honey begin. Instead of removing the mucilage, the coffee is laid out to dry. Different quantities of mucilage can be left on the beans, and different degrees of oxidation can be allowed to create different styles of honey processing:

White Honey

Yellow Honey

Red Honey

Purple Honey

Black Honey

Honey Processing in this day and age can also refer to it's physical state within an experimental process, such as double anaerobics, where one stage of processing might be done as a natural, de-pulped, and fermented a second time as a honey, and dried as such as well.

Other Classic Methods of note:

Wet hulled: Also called "semi-washed", or "giling basah".

Double washed: also known as Kenya style. This is a washed coffee with a submerged stage during fermentation.

Newer methods: (coming soon...)

Carbonic Maceration:

Cherry ferments:

Anaerobic fermentations: